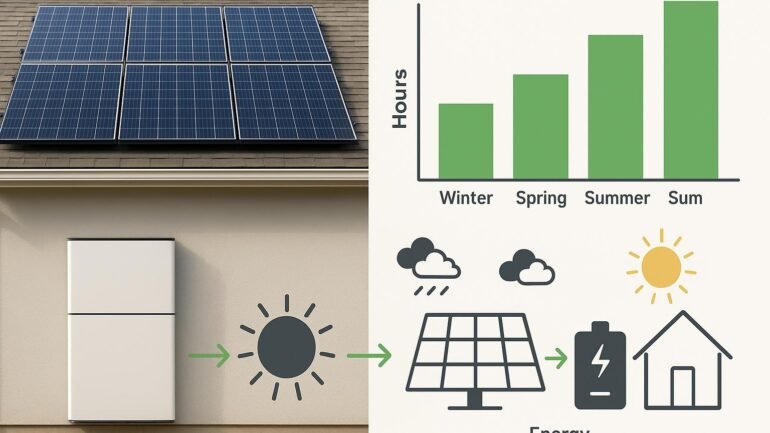

Real Sun Hours vs. Peak Sun Hours — what the numbers actually mean for solar projectsnnSolar sizing often hinges on peak or standard labels, but real-world results depend on real sun hours. Peak sun hours (PSH) are a standardized, idealized measure used for quick comparisons. Real sun hours vary with season, weather, angle, shading, and temperature, and they determine how much energy your system actually produces. The key is to translate PSH into realistic expectations for your location and season.nnWhat this means in practice:n- PSH is a reference, not a guarantee. Energy you generate equals system rating (kW) times the daily real sun hours, adjusted for inefficiencies.n- Real sun hours are lower in winter and higher in summer, and shoulder seasons sit in between with more variability.n- Battery charging, inverter efficiency, temperature derating, and shading further shape actual energy output.nnHow to use PSH and real sun hours in sizing:n1) Start with location-specific PSH values from trusted sources, then translate them to daily energy using real sun hours data.n2) Use historical weather data (cloud cover, irradiance, day length) to estimate seasonal energy delivery.n3) Combine with system efficiency factors (inverter, wiring, battery round‑trip) to estimate annual energy.n4) Validate with monthly or seasonal targets to avoid over/under-sizing for winter or summer extremes.nnSeasonal Sun Hours Variability — winter vs summer and the shoulder seasonsnnSeasonal sun hours are not the same across the year. In most climates:n- Winter: shorter days, more variable weather, and lower irradiance reduce real sun hours. Expect lower daily energy per kilowatt of solar installed.n- Summer: longer days and often clearer skies raise real sun hours, increasing daily energy production.n- Shoulder seasons: transitional and variable; week-to-week changes are common as weather patterns shift. The key for planning is to model winter rigor and then check how much summer surplus you may gain, not assume a flat year.nnHow weather data sources translate into system sizingnnReliable sizing relies on credible data and a clear conversion to usable energy. Practical steps:n- Gather long-term irradiance and cloud cover data for your location from sources such as PVWatts, NREL databases, or local meteorological stations.n- Convert monthly or daily irradiance into expected kWh per kW of installed PV, then apply seasonal multipliers to reflect real sun hours.n- Include location-specific temperature effects that reduce panel output and inverter efficiency during extreme conditions.n- Use these seasonal estimates to set target energy, storage needs, and backup margins.nnBattery Lifecycles in Real Use — degradation, depth of discharge, and temperature effectsnnBattery choice and usage patterns matter as much as panel output. Real-world life is driven by cycles, DoD (depth of discharge), and temperature:n- Deeper discharges (higher DoD) shorten cycle life more than shallow daily cycles.n- Temperature accelerates aging: heat drives faster degradation; cold can reduce capacity temporarily but typically isn’t as damaging as heat.n- Charging rate and inverter efficiency also influence longevity and performance.nnHow to estimate cycle life under seasonal usagennA practical approach without vendor-level fatigue curves:n1) Estimate annual cycles by season from your usage and storage plan (e.g., winter daily cycling for heating support, summer infrequent cycling for daytime use).n2) Determine a practical average DoD for your pattern (lower DoD typically yields longer life).n3) Use the manufacturer’s cycle-life curves to map cycles at your DoD to expected life, applying a temperature derating factor if you operate in extreme temperatures.n4) Build a conservative reserve into storage capacity to maintain reliability as the system ages.nnPractical Sizing Rules of Thumb for Seasonal PlanningnnThree simple rules you can apply today:n- Rule 1: Size for winter reliability. Prioritize enough storage and PV to cover average winter daytime deficits and cloudy days, so you don’t rely on back-up fuel or grid draw.n- Rule 2: Add seasonal headroom. Plan for at least 10–20% more PV capacity than the bare winter need to capture summer surplus and accommodate temperature losses.n- Rule 3: Allow for aging and temperature. Include a 10–15% usable-storage capacity buffer to withstand battery degradation and winter temperature swings over time.nn3 simple rules with example scenariosn- Scenario A (cold climate, moderate load): A 5 kW PV system backed by a 12 kWh usable storage plan yields solid winter reliability, with expected summer surplus that can be stored for shoulder seasons.n- Scenario B (mixed climate, higher daily use): An 8 kW system with 16–20 kWh usable storage provides strong winter margin and ample summer storage for peak days and grid outages.n- Scenario C (warm, sunnier location): A 6 kW system with 10–14 kWh usable storage can cover most daily needs, with reliable summer generation and manageable winter shortfalls through modest storage.nnDebunking Myths and Avoiding Common Sizing Pitfallsn- Myth: More sun hours automatically equal more usable energy. Reality: Real sun hours are tempered by weather, shading, and system losses; don’t rely on PSH alone.n- Myth: Winter means no solar. Reality: Solar can be very viable in winter with proper sizing and storage, though production per kW is lower.n- Myth: Battery life is immune to temperature. Reality: Heat accelerates aging; design for temperature resilience and include thermal management.n- Pitfall: Under-sizing for winter or over-relying on summer surplus. Build a winter-focused base with a safety margin, and use seasonal data to calibrate storage.n- Pitfall: Ignoring DoD effects. Deeper cycles reduce life; balance daily use with achievable DoD to maximize longevity.nnTools, Measurements, and Next Steps — how to apply this in your projectnnTo put these ideas into action:n- Collect local monthly electricity use and historical solar production data for your site.n- Use a reputable solar calculator or software to translate irradiance into expected production by month.n- Install monitoring to track actual performance versus forecast and refine sizing over time.n- Work with a solar professional to tailor panel tilt, shading analysis, and storage configuration to your climate and goals.nnConclusion: Real sun hours drive smarter sizing. By separating real sun hours from PSH, accounting for seasonal variability, and planning for battery aging, you can design a system that performs consistently year-round, even in winter. This approach supports smarter solar investments, resilient winter planning, and less maintenance over the system life.n