Proper winter maintenance keeps your solar system producing maximum power throughout the coldest months. Many DIY solar owners discover that cold weather actually improves panel efficiency. However, winter brings unique challenges that require proactive care.

Snow, ice, and freezing temperatures can significantly impact your system’s performance if left unaddressed. Fortunately, most winter maintenance tasks are straightforward and require minimal technical expertise. This guide covers everything you need to keep your panels, batteries, and wiring operating smoothly all season long.

Snow Removal Techniques for Solar Panels

Snow accumulation blocks sunlight and reduces energy production to nearly zero. Most panels shed light snow naturally due to their smooth surface and steep angle. However, heavy snow requires manual removal to restore full power generation.

Use a soft-bristled brush or specialized solar panel snow rake for safe removal. Never use metal tools or sharp objects that could scratch the panel surface. Work from the bottom up to prevent falling snow from hitting you directly.

For ground-mounted systems, removal is straightforward and safe from ladders. Proper panel placement makes winter maintenance much easier and safer. Roof-mounted panels require extreme caution and may need professional service.

Temperature differences can cause rapid melting, creating dangerous ice patches below panels. Therefore, always check the ground conditions before beginning any maintenance work. Additionally, warm water can help loosen stubborn ice without damaging panel surfaces.

Battery Care in Freezing Temperatures

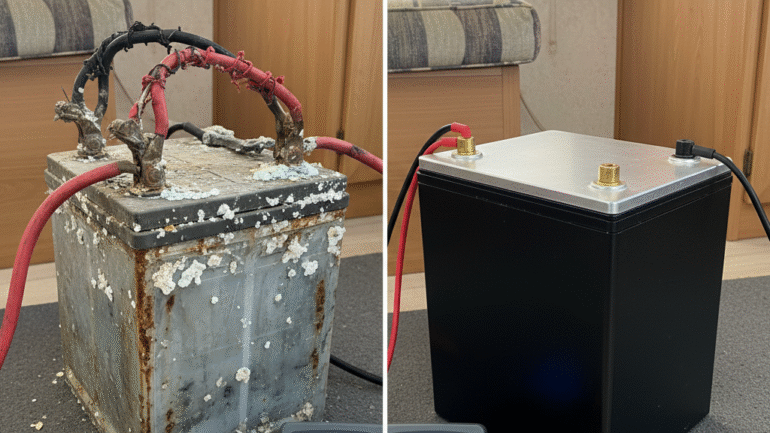

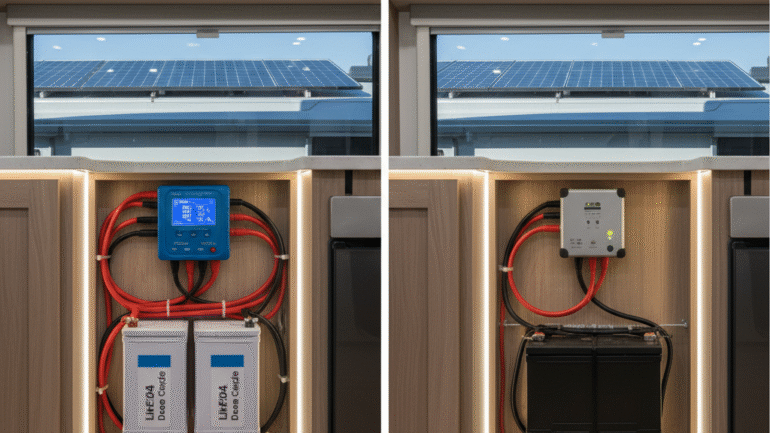

Cold weather dramatically affects battery performance and lifespan across all battery types. Lithium batteries typically shut down completely below freezing to prevent permanent damage. Lead-acid batteries lose significant capacity but continue functioning at reduced levels.

Insulation boxes or battery blankets help maintain optimal operating temperatures. Many DIY enthusiasts build simple insulated enclosures using foam board and reflective materials. Consequently, batteries stay warmer and maintain better performance throughout winter months.

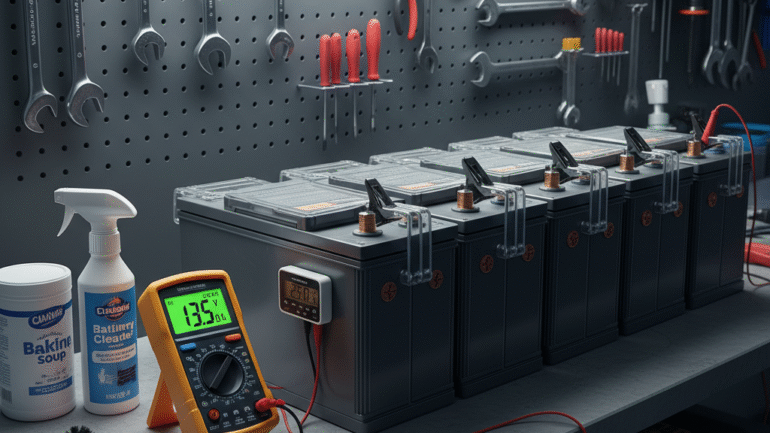

Monitor voltage levels more frequently during cold snaps to prevent over-discharge. Cold batteries charge more slowly and require extended charging periods. Furthermore, avoid charging frozen batteries, as this can cause permanent damage or safety hazards.

Consider relocating portable batteries to heated spaces during extreme cold. This strategy works particularly well for RV systems and small backup units. However, ensure adequate ventilation for lead-acid batteries that produce hydrogen gas during charging.

Temperature Monitoring Systems

Digital thermometers with remote sensors provide real-time battery temperature data. Place sensors directly on battery cases for accurate readings. Most lithium batteries include built-in temperature protection that prevents operation below 32°F.

Set up temperature alerts to notify you when batteries approach critical thresholds. Many smartphone apps connect to Bluetooth thermometers for convenient monitoring. This proactive approach prevents costly battery damage from temperature extremes.

Winter Performance Expectations

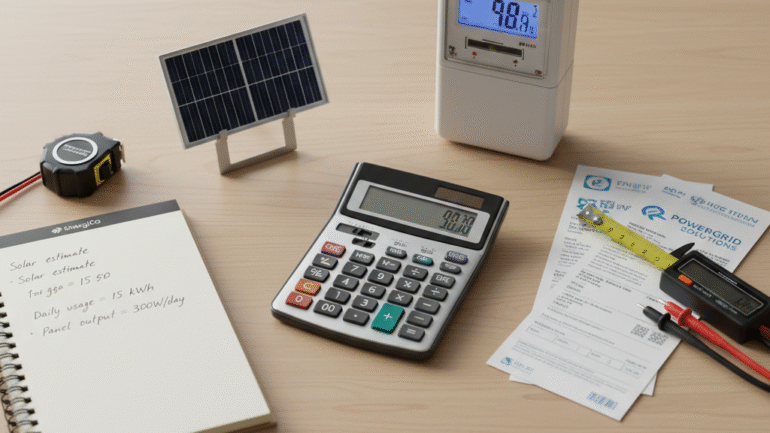

Solar panels actually perform better in cold weather due to improved electrical efficiency. However, shorter days and low sun angles significantly reduce total daily energy production. Expect 40-60% less power generation compared to summer months in most locations.

Plan your energy usage accordingly by reducing non-essential loads during winter. Cutting energy needs before adding more panels often proves more cost-effective than system expansion. Prioritize critical loads like lighting, communication, and heating systems.

Cloud cover further reduces winter performance, making battery storage more important. Overcast skies can persist for days, requiring larger battery banks for reliable power. Therefore, winter operation often reveals whether your system is properly sized for year-round use.

Track daily production to identify performance patterns and potential issues. Sudden drops in output may indicate snow coverage, equipment problems, or wiring issues. Regular monitoring helps distinguish between normal seasonal variation and actual system problems.

Seasonal System Adjustments

Adjustable mounts allow panel angle optimization for low winter sun positions. Increase tilt angles by 10-15 degrees from summer settings for better performance. Fixed mounts should be set at latitude plus 15 degrees for winter optimization.

Clean panels more frequently due to winter grime and salt residue from roads. Use distilled water and soft cloths to avoid scratching the surface. Consequently, clean panels can produce 20-30% more power than dirty ones during low-light conditions.

Check all connections for corrosion caused by moisture and temperature cycling. Tighten loose connections that may have developed from thermal expansion and contraction. Additionally, apply dielectric grease to prevent future corrosion issues.

Consider adding wind deflectors if your area experiences harsh winter storms. Strong winds combined with snow can stress mounting systems and damage panels. Simple barriers can redirect airflow and reduce snow accumulation on panel surfaces.

Wiring Inspection Checklist

Examine all outdoor wiring for cracking, brittleness, or damage from ice formation. UV-rated cables can become brittle in extreme cold and crack under stress. Replace any damaged sections before they cause system failures or safety hazards.

Ensure all junction boxes remain sealed and moisture-free throughout winter weather cycles. Water infiltration followed by freezing can crack enclosures and damage connections. Silicone sealant provides additional protection around entry points and mounting hardware.

Emergency Preparedness

Winter storms can knock out grid power for extended periods, making solar backup systems crucial. Building emergency power systems provides peace of mind during severe weather events. Test your backup capabilities before storms arrive.

Keep spare fuses, breakers, and basic tools accessible for quick repairs. Ice storms can damage components unexpectedly, requiring immediate attention. Stock up on battery maintenance supplies like distilled water and terminal cleaners.

Document your system configuration with photos and wiring diagrams for troubleshooting reference. Emergency situations are not the time to figure out complex wiring schemes. Clear documentation speeds up repairs and reduces stress during outages.

Practice switching to backup mode before you actually need it during an emergency. Familiarity with your system’s operation prevents costly mistakes during high-stress situations. Moreover, regular testing reveals potential issues before they become critical problems.

Professional vs. DIY Maintenance

Most winter maintenance tasks are well within DIY capabilities for ground-mounted and accessible systems. However, roof work during winter conditions requires professional expertise for safety. Ice and snow create extremely hazardous conditions that can cause serious injuries.

Electrical troubleshooting should be left to qualified technicians, especially in wet conditions. Water and electricity create deadly combinations that require specialized knowledge and safety equipment. Know your limits and call professionals when necessary.

Annual professional inspections can identify developing issues before they cause system failures. Certified technicians have specialized tools and training to spot problems that DIY owners might miss. This investment often pays for itself by preventing expensive repairs.

Keep detailed maintenance records for warranty purposes and system optimization. Many manufacturers require professional service for warranty coverage on larger systems. Documentation also helps track performance trends and identify when components need replacement.